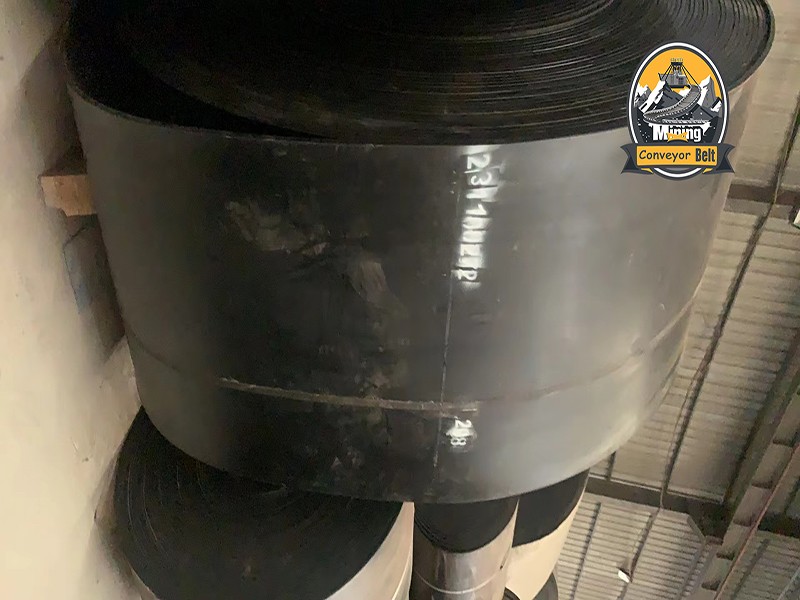

EP-170 Robust Polyester Conveyor Belt polyester corrugated sidewall rubber conveyor belt

Brand Xiamen Mining

Product origin Xiamen

From a quality control standpoint, a conveyor belt isn't just a product; it's a critical component that needs to meet stringent standards to ensure operational efficiency and safety. Today, I’m focusing on the EP-170 Polyester Conveyor Belt, examining the key factors that contribute to its overall quality and performance.

EP-170: Examining the Quality from the Inside Out

The designation "EP-170" immediately provides crucial information for quality assessment. The "EP" confirms the core material is polyester, known for its inherent strength and resistance to stretching. The "170" is a significant quality indicator, representing the single-ply tensile strength of the belt at 170 N/mm. This higher rating compared to lower EP numbers signals a greater capacity to withstand tension, a primary factor we scrutinize during inspection.

Key Factors Determining the Quality of the EP-170:

As a quality inspector, several factors are paramount in determining the overall quality and suitability of the EP-170:

Material Selection: The quality of the raw materials is the foundation. We verify that high-grade polyester fiber is used, ensuring it meets the required specifications for strength, wear resistance, and temperature stability. As previously noted, polyester fibers should exhibit a high modulus and low shrinkage rate.

Structural Integrity: The multi-layer woven construction is critical for the belt's strength and stability. We examine the weave pattern and bonding between layers to ensure there are no defects that could compromise the belt's integrity under load. Proper bonding is crucial to prevent delamination.

Cover Rubber Quality: The cover rubber protects the belt carcass and directly interacts with the conveyed materials. Key quality parameters include tensile strength (≥18Mpa as previously mentioned), abrasion resistance (with a target consumption of 0.8cm³/1.61Km), and resistance to specific environmental factors depending on the intended use (e.g., heat, oil, chemicals).

Adhesion Strength: The bond strength between the rubber covers and the fabric plies is a critical indicator of the belt's durability. We conduct tests to ensure the adhesion strength between plies is not less than 4.5N/mm, and the adhesion between the cover and ply is not less than 3.15N/mm, as previously specified.

Dimensional Stability: Maintaining consistent dimensions is vital for smooth operation and preventing tracking issues. We check for compliance with specified width and thickness tolerances. The low elongation characteristic of polyester is a key advantage here.

Quality Assurance: Addressing Key Questions:

From a quality control perspective, we ask specific questions to assess the EP-170:

Does the belt meet the specified tensile strength of 170 N/mm? This is a primary indicator of its load-bearing capacity.

Is the adhesion between the rubber covers and fabric plies sufficient to prevent separation under stress? Adequate adhesion is crucial for longevity.

Does the cover rubber meet the abrasion resistance standards for its intended application? This directly impacts the belt's lifespan when handling abrasive materials.

Are the belt's dimensions (width and thickness) within acceptable tolerances? Consistent dimensions ensure proper tracking and compatibility with the conveyor system.

The Verdict: Assessing the Quality of the EP-170:

The EP-170 Polyester Conveyor Belt, with its specified 170 N/mm tensile strength, demonstrates a commitment to robust performance. Rigorous quality control checks, focusing on material integrity, structural soundness, cover rubber properties, adhesion strength, and dimensional accuracy, are essential to ensure this belt meets the demands of its intended applications. A well-manufactured EP-170, passing these stringent quality assessments, provides assurance of a reliable and durable conveying solution.