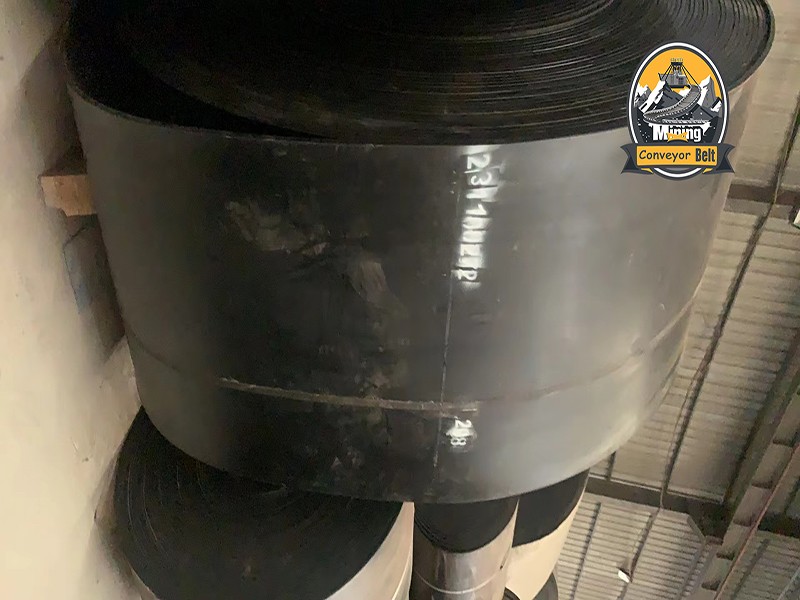

EP-350 High-Modulus Polyester Conveyor Belt nylon conveyor belt factory

Brand Xiamen Mining

Product origin Xiamen

For material handling challenges that push the very boundaries of what’s possible, requiring unparalleled strength and resilience, the EP-350 Polyester Conveyor Belt stands alone. This isn't just about moving materials; it's about conquering logistical hurdles in the most extreme and specialized environments. Let's delve into specific application scenarios and address the key concerns of users operating in these demanding fields.

EP-350: Tailored for the Extreme - Understanding its Capabilities

The designation "EP-350" immediately signals a product engineered for the absolute limit. The "EP" signifies the durable and reliable polyester fabric construction we’ve discussed. However, the "350" marks a significant leap, representing an extraordinary single-ply tensile strength of 350 N/mm. This rating signifies its capacity to withstand forces and loads that are beyond the reach of even high-performing standard belts.

EP-350 in Action: Addressing User Concerns Across Diverse Applications:

The exceptional capabilities of the EP-350 make it the preferred choice for highly specialized and demanding applications. Let’s examine some key scenarios and the critical questions users in these fields would ask:

Ultra-Deep Mining Operations: In the deepest and most challenging mining environments, the sheer weight of the overburden and the massive loads of extracted ore place immense stress on conveyor systems.

User Concern: Can the EP-350 handle the immense pressure and weight at these depths?

Answer: Absolutely. The exceptional 350 N/mm tensile strength provides the necessary safety margin and load-bearing capacity for these extreme conditions.

User Concern: Will abrasion from highly abrasive ore be a major factor in belt life?

Answer: While abrasion is a concern, the EP-350, when specified with appropriate high-grade cover rubber (meeting standards like consumption of 0.8cm³/1.61Km), offers significant resistance.

High-Stress Primary Crushing Circuits: The initial stages of material processing in mining and quarrying involve brutal impact forces from large, newly fractured rocks.

User Concern: Will the EP-350 withstand the repeated high-impact loading in primary crushing?

Answer: Yes, the robust construction of the EP-350, combined with the inherent impact resistance of polyester, is specifically designed for these demanding conditions.

User Concern: How frequently will we need to replace a belt under this extreme stress?

Answer: While replacement frequency depends on specific conditions, the EP-350 is engineered for longevity in harsh environments, minimizing downtime compared to lower-rated belts.

Extreme Incline Conveying for Massive Material Lifts: Transporting bulk materials up very steep inclines over long distances requires exceptional tensile strength and minimal elongation.

User Concern: Will the belt stretch excessively under the immense tension required for steep inclines?

Answer: No. Polyester’s inherent low elongation characteristics, stemming from its high modulus and low shrinkage rate, combined with the 350 N/mm tensile strength, make it ideal for these challenging layouts.

User Concern: Can the belt effectively grip and convey the material without slippage on such a steep incline?

Answer: Yes. When specified with appropriate cover patterns and considering factors like good troughability, the EP-350 ensures efficient material conveyance even on steep inclines.

Specialized Heavy Material Handling in Ports and Heavy Industry: Certain industries handle exceptionally dense or awkward materials that place unique stresses on conveyor systems.

User Concern: Is the EP-350 strong enough to handle the concentrated weight of exceptionally heavy items?

Answer: The 350 N/mm tensile strength makes it suitable for handling even the most substantial individual loads.

User Concern: Will the belt resist tearing or damage from materials with sharp edges or irregular shapes?

Answer: While no belt is impervious to damage, the EP-350’s robust construction and high-quality cover rubber offer significant resistance to tearing and impact damage.

The Unrivaled Choice for the Ultimate Challenge:

The EP-350 Polyester Conveyor Belt represents the pinnacle of engineering for the most extreme and specialized material handling applications. Its unparalleled tensile strength, combined with the inherent advantages of polyester, provides a level of performance and reliability that is unmatched. For industries pushing the boundaries of what’s possible, the EP-350 is the clear choice for conquering the toughest conveying challenges.