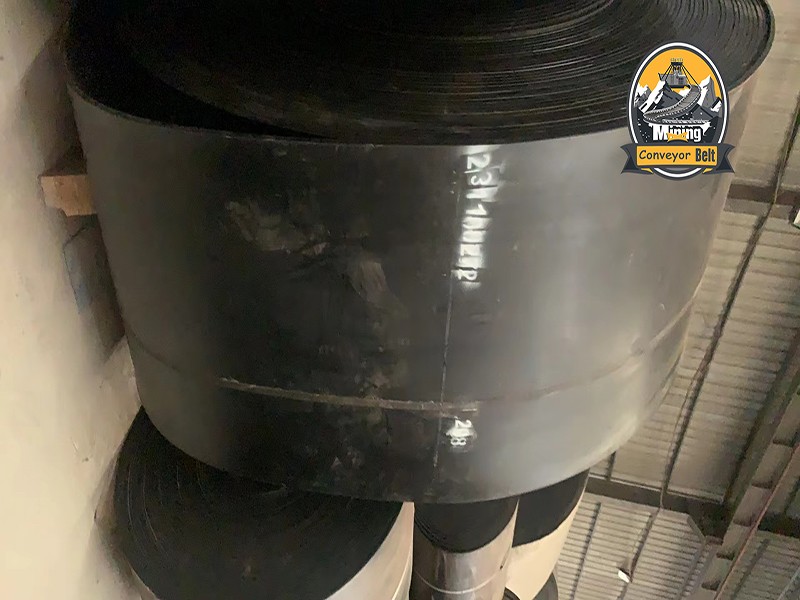

EP-300 High-Efficiency Polyester Conveyor Belt nylon fabric conveyor belt

Brand Xiamen Mining

Product origin Xiamen

When material handling demands the absolute pinnacle of strength and reliability, the EP-300 Polyester Conveyor Belt emerges as the definitive solution. Engineered for extreme conditions, its exceptional properties make it the go-to choice for the most demanding industrial applications.

EP-300: Engineered for Extreme Applications

The designation "EP-300" immediately signals its top-tier status. The "EP" confirms the foundation of polyester fabric, valued for its inherent durability and resistance to stretching. The "300," however, signifies a remarkable single-ply tensile strength of 300 N/mm. This ultra-high rating positions the EP-300 at the apex of performance, capable of handling loads and stresses that would overwhelm lesser belts.

Where EP-300 Excels: Real-World Application Scenarios:

The exceptional strength and durability of the EP-300 make it indispensable in several key industries and demanding applications:

Deep Mining Operations: In the depths of underground mines, where massive quantities of heavy ore and highly abrasive rock are continuously conveyed, the EP-300’s 300 N/mm tensile strength is crucial for reliable operation and preventing catastrophic failures. The inherent impact resistance of polyester is also vital in this harsh environment.

Primary Crushing Stages in Mining and Aggregate Processing: At the initial stages of material processing, conveyor belts are subjected to enormous impact forces from large, freshly broken rocks. The EP-300’s robust construction and high tensile strength are essential to withstand these extreme conditions and maintain continuous material flow.

Long-Distance, High-Incline Conveying Systems: For transporting materials over significant distances and steep inclines, the tensile strength of the conveyor belt is paramount. The EP-300’s minimal elongation properties, thanks to the high modulus and low shrinkage rate of polyester, combined with its 300 N/mm tensile strength, ensures reliable and efficient conveying even on challenging layouts.

Heavy Industrial Processing with Extreme Material Demands: Industries dealing with exceptionally heavy, abrasive, or high-impact materials rely on the EP-300. This includes specific applications in steel mills, heavy chemical processing plants, and large-scale construction projects where the demands on the conveyor belt are at their absolute maximum.

Key Considerations for Extreme Applications:

When deploying the EP-300 in these demanding scenarios, several factors come into play:

Why is the EP-300 preferred for the immense loads in deep mining? Its 300 N/mm tensile strength provides the necessary capacity and safety margin for handling extremely heavy ore.

How does the EP-300 withstand the constant impact at primary crushing stages? The robust polyester construction and durable cover rubber are engineered for high impact resistance.

Can the EP-300 handle long, steep inclines without excessive stretching? Yes, the low elongation characteristic of polyester, combined with its superior tensile strength, makes it ideal for such challenging layouts.

The Ultimate Solution for the Toughest Jobs:

The EP-300 Polyester Conveyor Belt represents the pinnacle of performance for the most demanding material handling applications. Its exceptional tensile strength, coupled with the inherent durability and stability of polyester, makes it the definitive choice for industries facing the toughest conveying challenges. When reliability and the ability to handle extreme conditions are non-negotiable, the EP-300 stands ready to deliver.