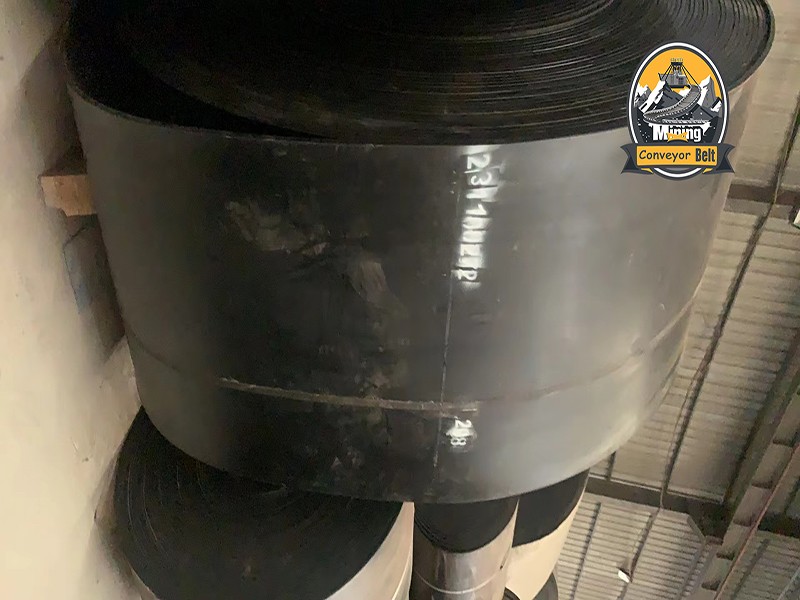

The EP-500 Polyester Conveyor Belt nylon rubber conveyor belt

Brand Xiamen Mining

Product origin Xiamen

Having explored a range of polyester conveyor belts, from the robust EP-80 to the powerful EP-400, we now arrive at the apex of this series: the EP-500 Polyester Conveyor Belt. This article serves as a comprehensive summary, drawing upon the wealth of information we've discussed to provide a complete understanding of this top-tier product.

EP-500: Synthesizing Strength, Durability, and Reliability

The designation "EP-500" encapsulates the culmination of the qualities inherent in polyester conveyor belt technology. The "EP" signifies the foundational polyester fabric construction, renowned for its high modulus and low shrinkage rate, contributing to exceptional dimensional stability. The "500" represents the zenith of tensile strength within this product line, indicating an extraordinary single-ply tensile strength of 500 N/mm. This remarkable figure underscores its capacity to handle the most extreme loads and stresses encountered in material handling.

Key Features and Benefits: A Consolidated Perspective

Across our discussions, several key features and benefits of polyester conveyor belts have emerged, all culminating in the impressive EP-500:

Unmatched Tensile Strength: Reaching 500 N/mm, the EP-500 offers the highest level of resistance to тяговое усилие, making it suitable for the most demanding applications.

Exceptional Dimensional Stability: The inherent properties of polyester ensure minimal elongation during operation, crucial for maintaining consistent performance and reducing downtime.

Superior Water Resistance: Polyester’s strong resistance to water and steam erosion prevents delamination and extends the belt's lifespan, even in humid environments.

Excellent Impact and Wear Resistance: Engineered to withstand the impact and abrasion associated with conveying heavy and abrasive materials, often featuring cover rubber with a tensile strength of ≥18Mpa and an abrasion loss of 0.8cm³/1.61Km.

Robust Construction: Typically featuring a multi-layer weave with excellent adhesion strength between plies (≥ 4.5 N/mm) and between the cover and ply (≥ 4 N/mm).

Resistance to Biological Degradation: Polyester offers good resistance to biological corrosion, enhancing its durability.

Good Troughability: The EP canvas construction allows for effective conveying of bulk materials.

Wide Range of Applications: Suitable for various industries, including mining, coal, ports, metallurgy, power, chemicals, and construction, with the EP-500 specifically targeting the most extreme scenarios.

Understanding the Construction: A Deep Dive

As we’ve learned, polyester conveyor belts like the EP-500 typically consist of:

EP Canvas Carcass: The core strength member, with polyester fibers in the warp (longitudinal direction) for tensile strength and nylon fibers in the weft (transverse direction) for tear resistance and flexibility.

Cover Rubber: Protecting the carcass and interacting with the conveyed material. Its properties, including tensile strength and abrasion resistance, are crucial for performance and longevity. Different types of rubber can be used to provide specific properties like Cold-resistant, acid-resistant, alkali-resistant, oil-resistant, and wear-resistant.

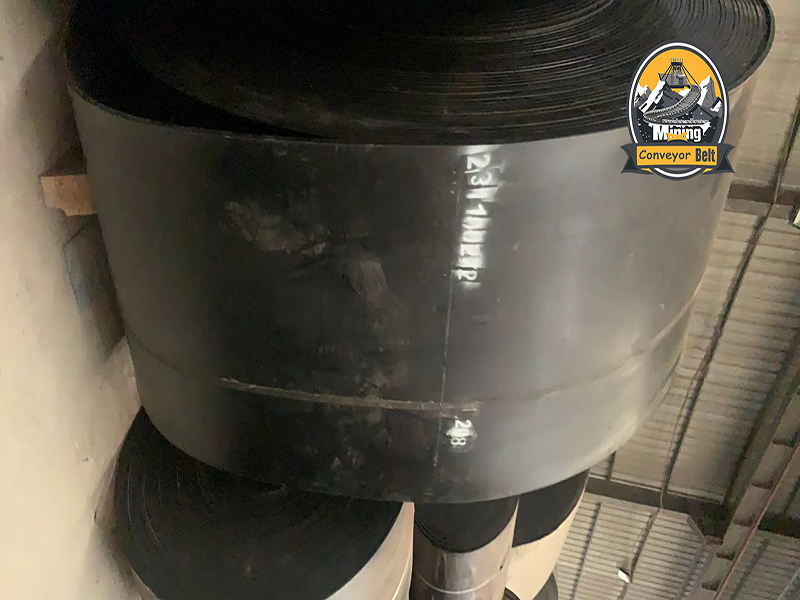

Multiple Layers (Plies): The number of layers contributes to the overall strength and load-bearing capacity. The notation like "1400×6" indicates a width of 1400mm and 6 layers.

Cover Thickness: The thickness of the top and bottom covers, often denoted as "(5+2)" for 5mm top and 2mm bottom, provides protection against wear and impact.

Applications Across Industries: A Broad Spectrum

While various EP-rated belts cater to different needs, the EP-500 is specifically designed for the most demanding applications, including:

Ultra-Deep Mining: Handling immense loads and highly abrasive materials at great depths.

High-Stress Primary Crushing: Withstanding extreme impact forces from large rocks.

Long-Distance, High-Incline Conveying: Transporting heavy materials over challenging terrains.

Heavy Industrial Processing: In sectors dealing with exceptionally dense and challenging materials.

Ensuring Quality and Reliability: Key Considerations

Quality control is paramount in ensuring the performance of EP-rated belts. Key factors include:

Material Selection: Utilizing high-quality polyester fibers.

Structural Design: Ensuring proper multi-layer weaving and bonding.

Surface Coating: Applying appropriate coatings for enhanced friction and anti-slip properties.

Technical Processing: Employing techniques like pre-tensioning to improve dimensional stability.

Adhesion Strength Testing: Verifying the bond between layers and covers.

Tensile Strength Testing: Confirming the belt meets the specified strength rating.

Abrasion Resistance Testing: Assessing the wear resistance of the cover rubber.

Addressing User Needs: A Holistic Perspective

Throughout our discussions, we’ve considered various user perspectives. The EP-500, from a consumer's viewpoint, offers unparalleled strength and reliability. For a manufacturer, it represents a high-performance solution for demanding applications. A quality inspector would focus on its adherence to stringent quality parameters. A high-end consumer values its premium performance and longevity. Ultimately, the EP-500 aims to meet the needs of those requiring the absolute best in conveyor belt technology.

The EP-500: The Apex of Polyester Conveyor Belt Technology

In conclusion, the EP-500 Polyester Conveyor Belt represents the pinnacle of this product line. Its exceptional 500 N/mm tensile strength, combined with the inherent advantages of polyester – including dimensional stability, water resistance, and durability – makes it the ultimate solution for the most challenging and demanding material handling applications across various industries. It embodies the highest standards of performance, reliability, and longevity in polyester conveyor belt technology.