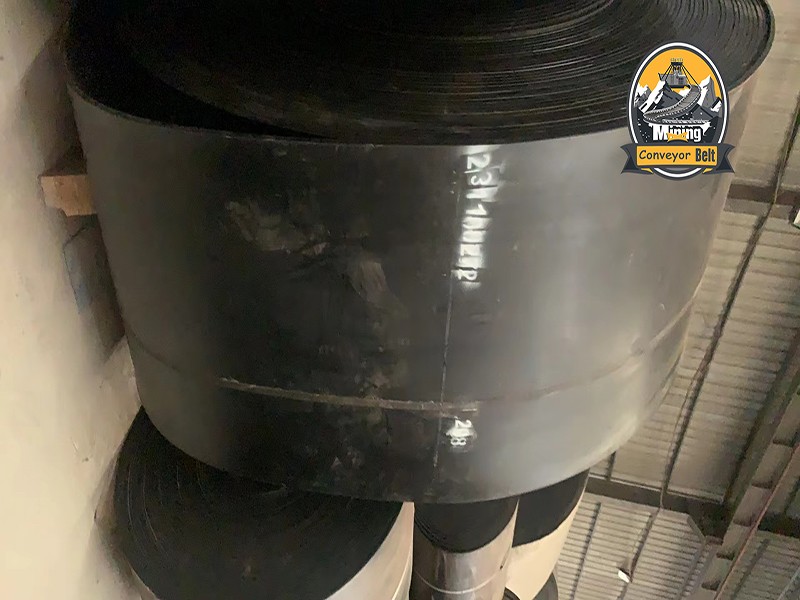

EP-80 Polyester Conveyor Belt nylon conveyor belt suppliers

Brand Xiamen Mining

In the demanding world of industrial material handling, efficiency and reliability are paramount. One component that plays a crucial role in ensuring smooth operations is the conveyor belt. Among the various types available, the EP-80 Polyester Conveyor Belt stands out for its robust construction and versatile applications.

What is an EP-80 Polyester Conveyor Belt?

As the name suggests, the "EP" signifies that the belt's carcass is made of polyester fabric. You might also hear it referred to as a Polyester Conveyor Belt, Wear-Resistant Conveyor Belt, or even a Cement Conveyor Belt, highlighting some of its common uses. The "80" in EP-80 is significant. As you've taught me, in the model number, the number following "EP" indicates the single-ply tensile strength in N/mm. Therefore, EP-80 signifies a polyester belt with a single-ply tensile strength of 80 N/mm.

Key Features and Benefits:

Drawing upon the information you've provided, the EP-80 Polyester Conveyor Belt boasts several key advantages:

High Strength and Low Elongation: Polyester fibers possess a high modulus and low shrinkage rate. This translates to excellent dimensional stability and minimal elongation during operation. This is crucial for maintaining consistent performance, especially in applications requiring high precision.

Excellent Water Resistance: As you pointed out, polyester offers strong resistance to water and steam erosion. This ensures the adhesive properties remain strong, preventing delamination and extending the belt's lifespan, even in humid environments.

Good Troughability: The EP canvas construction provides good troughability, allowing the belt to effectively carry bulk materials without spillage.

Impact and Wear Resistance: Polyester belts exhibit good impact resistance and wear resistance, making them suitable for handling abrasive materials like ores and coal. You mentioned that the covering rubber should have a tensile strength of ≥18Mpa and an abrasion loss of 0.8cm³/1.61Km for optimal performance in such conditions.

Resistance to Biological Degradation: Polyester is known for its good resistance to biological corrosion, further enhancing its durability.

Lightweight Construction: Compared to cotton canvas belts, polyester allows for a thinner and lighter belt body while maintaining strength. This contributes to energy savings and can potentially reduce the required drive power.

Where is the EP-80 Polyester Conveyor Belt Used?

Based on your insights, the EP-80 is well-suited for various industries and applications, including:

Mining: Transporting ores and minerals.

Coal Industry: Handling raw coal.

Ports: Conveying bulk materials.

Metallurgy: Moving materials in processing plants.

Power Plants: Handling coal and other fuels.

Chemical Industry: Transporting various materials (excluding hot or oily substances).

Construction: Conveying sand, gravel, and other aggregates.

Common Questions About EP-80 Polyester Conveyor Belts:

What kind of materials can the EP-80 handle? It's ideal for bulk materials like ores, coal, sand, and stone, but avoid hot or oily substances.

What are the main advantages of using an EP-80 belt? Key benefits include high strength, dimensional stability, water resistance, and good wear resistance.

Is the EP-80 suitable for long-distance conveying? Yes, its low elongation properties make it suitable for both long and short-distance conveying.

In Conclusion:

The EP-80 Polyester Conveyor Belt stands as a reliable and cost-effective solution for numerous industrial material handling needs. Its polyester construction provides a strong, dimensionally stable, and durable belt capable of withstanding demanding conditions and efficiently transporting a wide range of bulk materials. For industries seeking a dependable conveyor belt for applications involving impact, abrasion, and exposure to moisture, the EP-80 is a compelling choice.