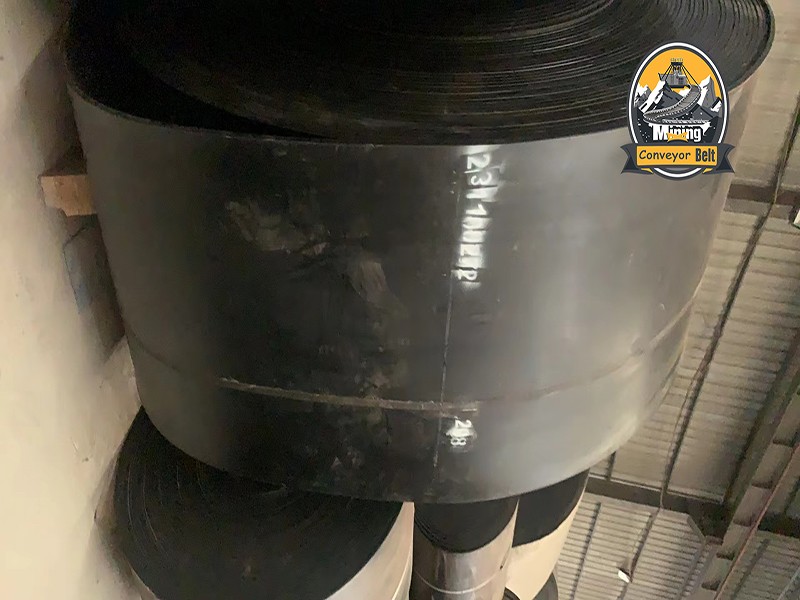

EP-250 Heavy-Duty Polyester Conveyor Belt polyester conveyor belt factory

Brand Xiamen Mining

Product origin Xiamen

When you're in the market for a conveyor belt, you're looking for something that delivers on its promises – strength, durability, and reliability. The EP-250 Polyester Conveyor Belt is engineered with these key selling points in mind, making it a compelling option for demanding applications.

EP-250: What Makes It a Top Performer?

The name itself hints at its capabilities. The "EP" signifies the trusted polyester fabric construction. But the "250" is where things get really interesting. This number denotes a significant single-ply tensile strength of 250 N/mm. For a consumer, this translates directly to exceptional strength and the ability to handle even heavier loads and more challenging materials. It’s the headline feature that screams performance.

My Top Questions About the EP-250:

As a consumer, several key questions come to mind when evaluating the EP-250:

What’s the biggest advantage of choosing the EP-250? Without a doubt, it’s the superior strength. That 250 N/mm tensile strength means it can handle significantly more stress and heavier materials compared to lower-rated belts.

How long will this belt actually last under tough conditions? Durability is paramount. The polyester construction inherently offers good resistance to wear and tear. You’ve previously mentioned that polyester belts have good impact resistance and wear resistance. Furthermore, the specified covering rubber with a tensile strength of ≥18Mpa and an abrasion loss of 0.8cm³/1.61Km suggests it’s built for longevity.

Can it handle the kind of tough, abrasive materials I work with? Absolutely. The combination of the high-strength polyester carcass and the robust cover rubber makes it well-suited for handling abrasive materials.

Am I going to be constantly adjusting this belt due to stretching? One of the key benefits of polyester is its low shrinkage rate, leading to excellent dimensional stability. This means minimal stretching during operation, reducing maintenance and downtime.

Where Would You Actually Use an EP-250? Real-World Applications:

The EP-250’s impressive strength and durability make it ideal for a range of demanding applications:

Large-Scale Mining Operations: For the continuous transport of heavy ores, minerals, and overburden where high tensile strength and abrasion resistance are crucial.

Heavy-Duty Aggregate Processing: In quarries and aggregate plants where the belt needs to withstand the impact and wear of rocks, gravel, and crushed stone.

High-Volume Port Facilities: For handling large quantities of bulk materials like coal, iron ore, and grains, where reliability and the ability to handle significant loads are essential.

Industrial Recycling Plants: Where the conveyor belt may encounter a variety of heavy and potentially abrasive materials.

Cement Manufacturing: For transporting raw materials like limestone and clinker, which can be heavy and abrasive.

The Bottom Line: Why Choose the EP-250?

The EP-250 Polyester Conveyor Belt is a powerhouse designed for demanding applications. Its key selling point is its exceptional strength, backed by the robust properties of polyester and a durable cover rubber. For consumers who need a conveyor belt that can handle heavy loads, resist wear and tear, and minimize downtime due to stretching, the EP-250 offers a compelling and reliable solution. It’s a clear choice when performance and durability are top priorities.