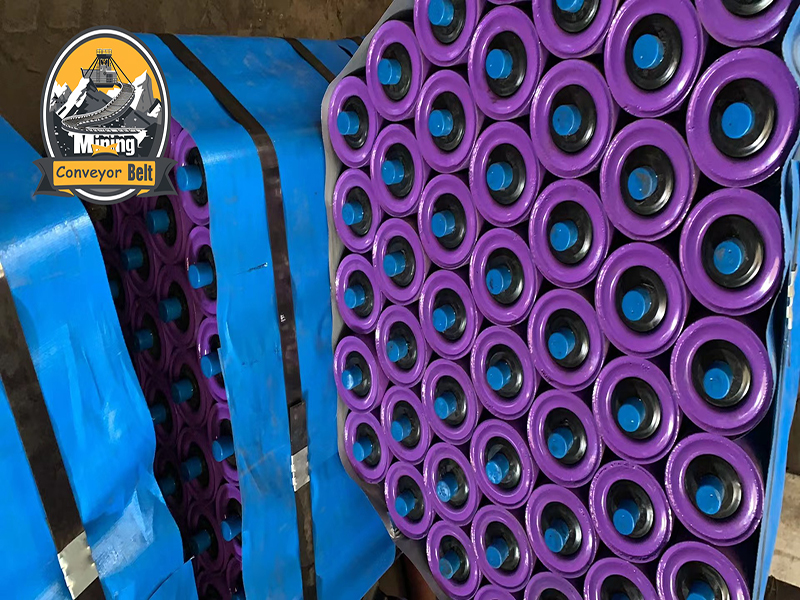

Conveyor Belt Elevates Material Handling with the New Triple Roller manufacture

Brand Xiamen Mining

Product origin Xiamen

Triple Rollers, also known as Three-Chain Idlers, are a specialized type of troughing idler designed to provide superior support for conveyor belts and the materials they carry. They play a critical role in ensuring smooth and efficient conveyor operation, contributing significantly to the longevity of the conveyor belt itself. This article will introduce Triple Rollers, address common questions from a user's perspective, and highlight their key features and benefits based on the comprehensive information you've provided.

What are Triple Rollers and Why are They Important?

Triple Rollers are a specific type of troughing idler designed to support the conveyor belt and the weight of the transported materials. They are engineered to ensure flexible and reliable operation, minimizing friction between the belt and the idlers. This is crucial because the conveyor belt itself represents a significant investment, accounting for over 25% of the total cost of a conveyor system. While seemingly small components, high-quality idlers like Triple Rollers are not easy to manufacture and are essential for optimal conveyor performance.

My Questions as a User and How Triple Rollers Provide the Answers:

1. What is the primary function of a Triple Roller?

Answer: Like other idlers, the primary function of a Triple Roller is to support the conveyor belt and the material being transported. The "triple" or "three-chain" design likely provides enhanced support and load distribution compared to single-roller idlers, although the provided information doesn't detail the exact mechanism.

2. What are the key criteria for assessing the quality of an idler?

Answer: The quality of an idler, including Triple Rollers, is judged based on its radial run-out, flexibility, and axial movement. Previous information also mentioned dustproof performance, waterproof performance, and axial load capacity as important factors.

3. How important is the idler's role in the overall conveyor system?

Answer: Idlers are crucial components. They represent 35% of the total cost of a belt conveyor and are responsible for over 70% of the resistance. Their quality directly impacts the system's efficiency and the lifespan of the belt.

4. What is the typical service life of a well-maintained idler?

Answer: A well-maintained idler can achieve a service life of 20,000 hours or more.

5. What are the different types of idlers available?

Answer: Idlers are classified by material (e.g., rubber, ceramic, nylon, insulated) and by function/structure. The main categories are troughing idler sets, parallel idler sets, aligning idler sets, and impact idler sets. Triple Rollers belong to the troughing idler set category.

6. What are some examples of specific idler types within each category?

Answer:

Troughing Idlers: Include Triple Rollers, ordinary, forward-inclined, quick-change bearing, suspended, reversible, variable trough angle, transition, and V-type idlers.

Parallel Idlers: Include ordinary, comb, forward-inclined, steel-rubber, and spiral idlers.

Aligning Idlers: Include universal, friction-reversible, strong, taper, spiral, and combined idlers.

Impact Idlers: Include spring plate, impact ring, strong impact, adjustable elastic, and suspended idlers.

7. What are the consequences of using a poorly performing idler?

Answer: A poorly performing idler can lead to increased friction, premature belt wear, reduced efficiency, and higher operating costs. For instance, a misaligned idler can significantly reduce bearing lifespan. An idler with 1N of rotational resistance can have a bearing lifespan of 150,000 hours, while one with 3N resistance may only last 50,000 hours.

8. What industries commonly use idlers?

Answer: Idlers are used across various industries, including mining, metallurgy, ports, power plants, cement, chemicals, building materials, and food processing.

Conclusion:

Triple Rollers are a vital component in belt conveyor systems, designed to provide robust support and minimize friction, ultimately extending the life of the conveyor belt. Their design contributes to the smooth and efficient operation of the entire system. By focusing on key quality indicators like radial run-out, flexibility, and axial movement, and adhering to proper maintenance practices, users can maximize the 20,000+ hour service life of these idlers. The wide range of idler types available, including Triple Rollers, highlights the importance of selecting the right idler for specific applications and industries. Choosing high-quality idlers like Triple Rollers is a crucial investment that can lead to significant long-term cost savings and improved operational efficiency.