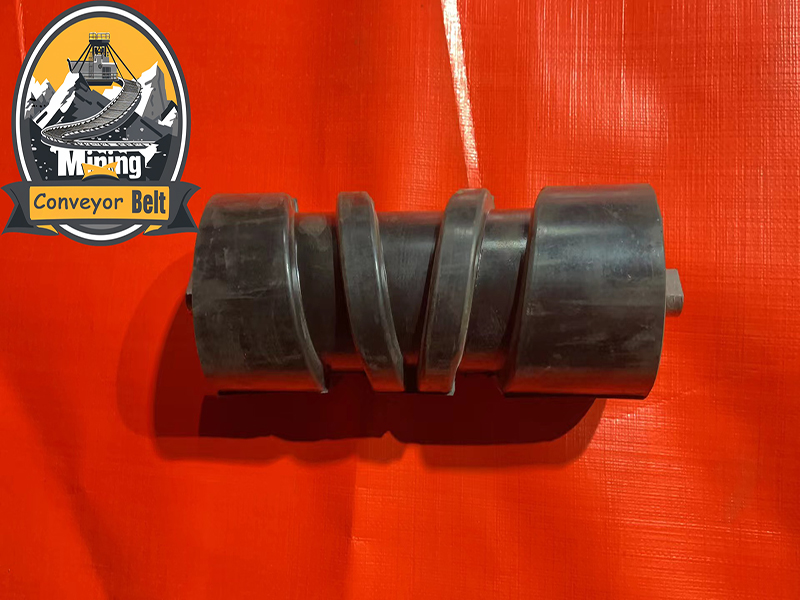

Conveyor Belt's Spring-Loaded Roller belt conveyor design roller support

Brand Xiamen Mining

Product origin Xiamen

Xiamen Mining's Spring-Loaded Roller enhances conveyor resilience and longevity, offering unmatched wear resistance. Designed for varied conditions, it minimizes impact at loading points, extending component life.

Think about where things can go wrong on a conveyor system. One of the biggest culprits? Impact. Whether it's heavy materials dropping onto the belt or just the constant jostling of the load, all that force can take a real toll. That's where Spring-Loaded Rollers come into play.

These aren't your standard, run-of-the-mill rollers. They're specifically designed to be part of the impact roller family, acting as shock absorbers for your conveyor belt. You see, when we talk about conveyor rollers , there’s a whole range of types out there, each with its own job. You’ve got your troughed rollers shaping the belt, parallel rollers for support, and self-aligning rollers keeping things straight. But when it comes to handling those sudden impacts, that’s where Spring-Loaded Rollers and other impact rollers like adjustable spring rollers , suspended rollers , rubber ring rollers , and heavy-duty impact rollers really shine.

So, if you're looking at your conveyor system and wondering how to protect it from damage, you might be asking:

"Why would I specifically need Spring-Loaded Rollers?"

That’s a great question. It boils down to cushioning the blow. Imagine dropping a heavy object onto a hard surface versus dropping it onto something with a bit of give. Spring-Loaded Rollers provide that "give." They’re designed to absorb the impact energy when materials land on the belt, preventing damage to both the belt itself and the supporting structure.

"How do Spring-Loaded Rollers compare to other types of rollers?"

Well, think about the main job of a roller: it’s there to support the conveyor belt and the weight of the materials being carried. As you mentioned, they need to be flexible and stable to do this job effectively. But Spring-Loaded Rollers have that extra layer of protection. While parallel rollers are great for general support and self-aligning rollers keep the belt tracking correctly, Spring-Loaded Rollers are the go-to when impact is a major concern.

"What makes a good quality Spring-Loaded Roller?"

Like any roller, quality comes down to a few key things. You want to look for good flexibility – the spring mechanism needs to work smoothly. Also, keep an eye on the axial movement and radial runout. These are indicators of how well the roller is made and how smoothly it will operate. As we’ve discussed before, the quality of the rollers has a direct impact on the lifespan of your conveyor belt, helping to reduce the friction between the two.

"Are there different materials used for Spring-Loaded Rollers?"

Absolutely. Just like other types of rollers, Spring-Loaded Rollers can be made from various materials depending on the application. You’ll see them made from ceramic, nylon, rubber, and even insulating materials, each offering different properties for different environments and materials being conveyed.

"How do I keep Spring-Loaded Rollers in good shape?"

The general rules for roller maintenance apply here too. You want to avoid disassembling them unnecessarily to protect the seals. Definitely don't let heavy objects hit the roller body directly. While they're built to handle impact on the belt, direct hits can cause damage. And, like any roller, periodic maintenance is key, the frequency of which depends on your operating environment and the loads you're handling. When replacing bearings, using original factory parts for the seals is always a good practice.

In short, Spring-Loaded Rollers are your frontline defense against impact damage on your conveyor system. They’re a specialized type of roller designed to absorb shocks and protect your valuable equipment. If you’re dealing with heavy or unevenly loaded materials, these rollers are definitely worth considering to extend the life of your conveyor belt and keep your operation running smoothly.