Why do the skirt and partition of the sidewall conveyor belt break first?

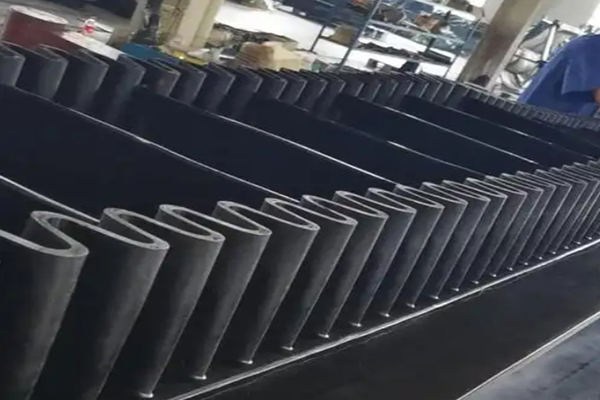

The sidewall conveyor belt is widely used in various material lifting and conveying because of its small footprint and low cost.... In actual production, the skirt and partition are often more seriously damaged than other places. What is the reason?

1. The main causes of damage:

1. Belt pressure wheel:

A. The speed of the large wheel and the small wheel is different, but the large and small wheels are welded together, forcing the speed of the small wheel to be the same as that of the large wheel. In this way, the small wheel and the top of the skirt form drag friction;

B. The diameter of the small wheel is large, and the top of the skirt is forced to be pressed down. In addition, the drag friction will cause the skirt to wear and crack quickly.

2. Check the defects of the long return roller. It cannot be seen from the photo. Are there any parts that are in direct contact with the skirt? Is the belt taut? If the belt is not taut, it will cause the belt to jump up and down and hit the roller during operation, causing the skirt to crack.

3. The distance between the short return roller and the skirt is small, and the top of the short roller directly contacts the worn skirt.

4. There is an obvious missing corner on the outside of the top of the partition, indicating that the partition has scratched the steel part.

2. Improvement suggestions:

1. The belt pulley must be replaced. The small wheel has a separate bearing so that it can rotate freely alone; the diameter of the small wheel is reduced. Under normal circumstances, it is almost in contact with the top of the skirt.

2. If the long return roller is in contact with the skirt, the long roller can be lowered so that the skirt does not contact it; or, the short roller can be raised so that the top of the skirt does not contact the long roller.

3. Adjust the distance between the end of the short roller and the skirt. In the case of deviation, the end of the roller does not wear against the skirt.

3. Key points:

1. The skirt and partition of the conveyor belt cannot directly contact the steel. Wherever there is contact, improvement measures must be taken to eliminate the contact point.

2. The function of the skirt is to block the material and prevent the conveyed material from scattering to both sides; the function of the partition is to carry the material and prevent it from sliding down, realizing the principle of large-angle conveying.

3. The maintenance principle is: A. Check whether there is direct contact between the damaged part and the equipment; B. Eliminate the hidden danger at that place.