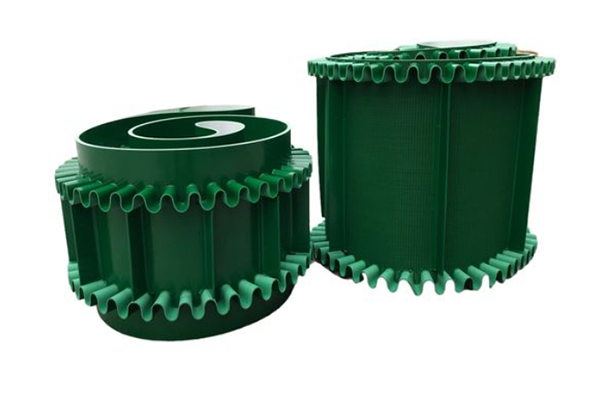

Product introduction: Skirt conveyor belt

The rubber surface material of PVC conveyor belt is polyvinyl chloride (PVC), and its composition is polyester fiber cloth and polyvinyl chloride rubber. Its working temperature is generally -10° to +80°, and its joint method is generally an international tooth joint. It has good lateral stability and is suitable for transmission in various complex environments.

Skirt conveyor belt is a conveying system, which is divided into two types: conveyor belt with skirt and no partition and conveyor belt with skirt and partition.

Product features: Skirt conveyor belt can continuously convey various bulk materials at any inclination angle of 0-90 degrees, with large conveying inclination, wide range of use and small footprint. No transfer point, reduced civil engineering investment, low maintenance cost, large conveying capacity and other characteristics, solve the conveying angle that ordinary conveyor belts or patterned conveyor belts cannot achieve. The corrugated sidewall conveyor belt can be designed as a complete conveying system according to requirements, avoiding intermittent conveying and complex conveying lifting system.

The corrugated sidewall conveyor belt can transport various bulk materials in horizontal, inclined, vertical and variable angle directions, from coal, ore, sand to fertilizer and grain.

The material particle size is not limited, ranging from very small particles to large particles of 400mm, and the conveying capacity can range from 1 cubic meter/hour to 6000 cubic meters/hour.

With the popularity of conveyor belts in industrial production, multiple varieties, high performance, lightweight, multi-function and long life are several aspects that manufacturers pay attention to. In industrial production, it is particularly important to use conveyor belts correctly. The following matters should be noted when using conveyor belts:

1. Avoid the rollers being covered by materials, causing poor rotation, prevent leakage from getting stuck between the roller and the belt, pay attention to the lubrication of the moving parts of the conveyor belt, but do not oil the conveyor belt;

2. Prevent the conveyor belt from starting under load;

3. If the conveyor belt deviates, take timely measures to correct it;

4. When the conveyor belt is found to be partially damaged, use artificial cotton to repair it in time to avoid expansion;

5. Avoid the conveyor belt from being blocked by the frame, pillars or block materials to prevent it from being broken and torn

Application range:

It has a wide range of uses, mainly used in food, tobacco, logistics, packaging and other industries. It is suitable for underground transportation in coal mines, and can also be used for material transportation in metallurgy and chemical industries.