What are the measures for optimizing and improving nylon conveyor belts?

Nylon conveyor belts are widely used in agriculture, industrial and mining enterprises, and transportation industries to transport various solid block and powder materials or finished items, playing an irreplaceable role in our lives. As the scope of conveyor belts expands, the original characteristics and advantages are gradually weakened. In order to have a longer-term development, corresponding measures need to be taken to solve it.

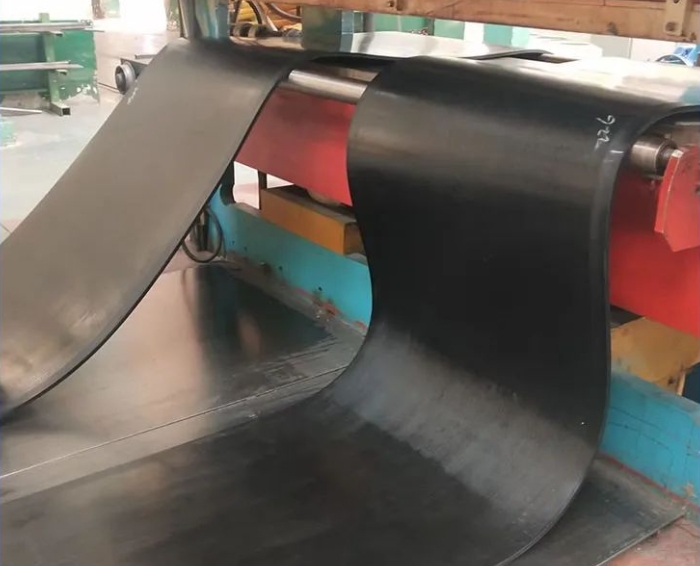

The technical standard requirement for the transverse rigidity value of nylon conveyor belts is not more than 0.05. After optimizing and improving the belt structure of the sidewall conveyor belt, the transverse rigidity detection value is 0.036 after adding a transverse rigidity reinforcement layer. The transverse deformation of the belt body is reduced after bearing, which can increase the bearing capacity by 15% to 20%. An effective measure to improve the transverse rigidity of large heavy-duty conveyor belts is to set a special composite rubber layer of polyester staple fibers that is specially mixed and calendered between the multi-layer tensile canvas layers of the flat base belt body.

That is, the polyester staple fibers are buried in the rubber layer in a single transverse direction of the belt body, thereby better increasing the service life of the conveyor belt. The rubber ratio of nylon conveyor belts is generally based on natural rubber, with a rubber content of about 50%. The sulfur system still uses the traditional system of sulfur and accelerators, and the accelerators are M and DM. The operation of the cold bonding method is similar to the vulcanization method, except that a special adhesive is used to bond the two ends of the belt without vulcanization.

The advantages of this method are that the strength of the joint is less reduced, the operation is simple, time-saving, and no special equipment is required. The tensile strength of the masking rubber is relatively high, and it is resistant to aging and corrosion, so it is the choice of masking rubber conveyor belts. The conveyor belt contacts high-temperature materials. If the conveyor belt conveys high-temperature materials, the materials with too high temperature will heat and melt the belt, resulting in serious damage to the conveyor belt.

The main function of the buffer rubber is to increase the adhesion, so it is used between the masking rubber and the belt core layer. The characteristics of the buffer rubber itself, such as high elasticity, less heat generation, and good heat dissipation, ensure good adhesion, so that it can be better used by people.