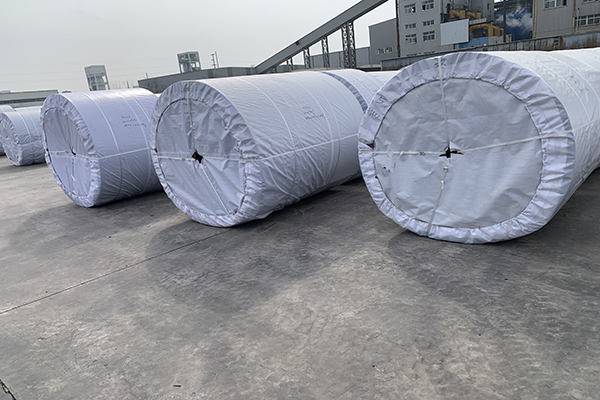

This is the skirt conveyor belt

With the development of domestic industry, the food, tobacco, medicine, agriculture, electronics and other industries have gradually applied lightweight skirt conveyor belts. Light skirt belts are welded from thermoplastic elastomers such as PVC and PU. They are flexible in processing and light in application.

Skirt conveyor belts are divided into two types: conveyor belts with skirts and no partitions and conveyor belts with skirts and partitions. It can continuously convey various bulk materials at any inclination angle from 0 to 90 degrees. It has the characteristics of large conveying inclination angle, wide range of use, small footprint, no transfer points, reduced civil construction investment, low maintenance costs, and large conveying capacity. It solves the problem of It achieves a conveying angle that cannot be achieved by ordinary conveyor belts or patterned conveyor belts. The corrugated edge conveyor belt can be designed into a complete conveying system according to requirements, avoiding intermittent conveying and complex conveying lifting systems.

The skirt lifting conveyor belt (corrugated edge conveyor belt) mainly consists of the following three parts: 1. High-strength and wear-resistant base belt with greater lateral stiffness and longitudinal flexibility. 2. High strength hot vulcanized rubber corrugated ribs. 3. Transverse partitions to prevent objects from sliding down. The bottom of the ribs and partitions and the base tape are hot vulcanized into one body. The height of the ribs and partitions can reach 40-630mm. Canvas is added to the ribs to enhance the tear resistance of the ribs.

With the popularity of conveyor belts in industrial production, multiple varieties, high performance, lightweight, multi-functional, and long life are the aspects that manufacturers are paying attention to. In industrial production, the correct use of conveyor belts is particularly important. When using conveyor belts, you should pay attention to the following matters: 1. Avoid the rollers being covered by materials, causing failure to rotate, and prevent leakage materials from getting stuck between the rollers and the belts. Pay attention to Lubricate the moving parts of the conveyor belt, but do not allow oil to stain the conveyor belt; 2. Prevent the conveyor belt from starting under load; 3. If the conveyor belt deviates, timely measures should be taken to correct it; 4. When the conveyor belt is found to be partially damaged, use artificial cotton to repair it in time. To avoid expansion; 5. Avoid the conveyor belt being blocked by the frame, pillars or block materials to prevent it from being broken or torn.

So how to solve the problems that often occur during the use of skirt conveyor belts?

1. What to do if the skirt baffle conveyor belt deviates?

Conveyor belt deviation often occurs during the production process, so we have added the function of guide strips to prevent deviation in the production of conveyor belts. Through the auxiliary adjustment of the guide bar, the damage to the conveyor belt itself caused by the deviation of the conveyor belt is effectively solved and the service life is extended.

2. What to do if the skirt baffle comes off?

Skirt falling off often occurs when using conveyor belts. Our company has improved the skirt mold and designed a traceless mold. The width of the skirt base has been widened to make the skirt stronger. We have adopted the skirt joint part The annular joint mode abandons the original thermal bonding process, effectively reducing the possibility of the skirt falling off.

3. What to do if the skirt baffle and baffle come off?

Baffles often come off during the use of conveyor belts. Our company provides professional pre-sales selection services based on customers' different usage environments. In addition, we have a complete set of removable molds to ensure the processing fastness of the baffles.