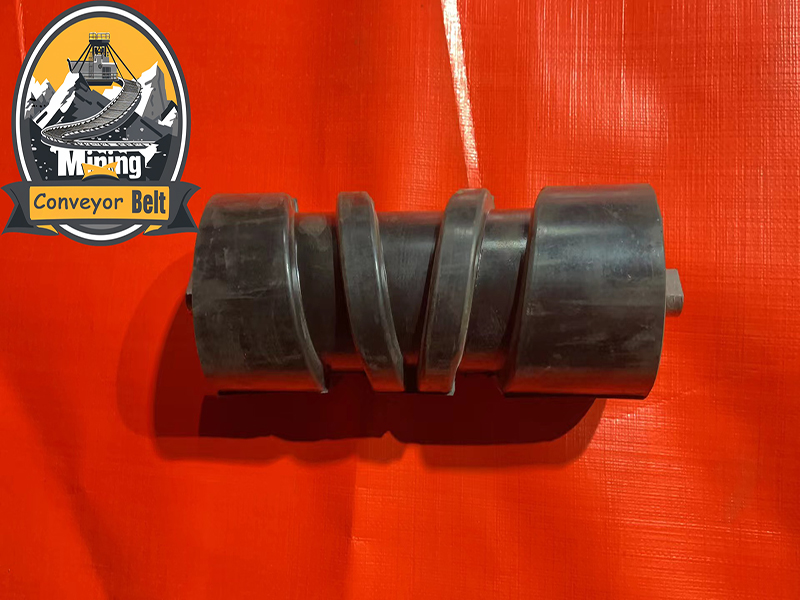

Conveyor Belt's Spring-Loaded Roller belt conveyor design roller support

Xiamen Mining's Spring-Loaded Roller enhances conveyor resilience and longevity, offering unmatched wear resistance. Designed for varied conditions, it minimizes impact at loading points, extending component life.

Introduction:

Xiamen Mining Conveyor Belt, a trailblazer in the conveyor industry, proudly presents the Spring-Loaded Roller, an innovative solution designed to significantly enhance the resilience and longevity of conveyor systems. As a critical component in dampening the impact at loading points, this roller variety, with its exceptional toughness – over ten times that of ordinary metals – sets new benchmarks in wear resistance. Let’s delve into the various models, installation principles, and maintenance strategies that underscore the importance of the Spring-Loaded Roller and its pivotal role in extending the life span of conveyor components.

Overview of the Spring-Loaded Roller:

The Spring-Loaded Roller is part of an extensive lineup of buffer rollers that includes models such as spring plate type, buffering ring type, heavy-duty buffering type, adjustable tension type, and hanging type. This range is engineered for use at the material loading sections of belt conveyors to diminish the impact on conveyor belts from falling materials.

Advantages of the Spring-Loaded Roller:

1.Diverse Models:

Xiamen Mining Conveyor Belt offers a variety of Spring-Loaded Rollers to suit different applications and operational conditions, allowing for targeted impact absorption where it matters most.

2.Enhanced Impact Resistance:

The advanced design of these rollers provides superior toughness and durability, significantly reducing wear on conveyor belts and preventing potential tears from hard objects.

Installation Principles of the Spring-Loaded Roller:

1.Increased Installation Density:

To maximize the effectiveness of Spring-Loaded Rollers, principles of dense installation are followed, ensuring comprehensive coverage and impact absorption.

2.Regular Inspection:

Routine checks and timely replacement of damaged rollers are crucial to maintaining system integrity, especially for conveyors with large drop distances where buffer airlock devices are recommended.

Performance Features to Consider:

Factors such as dust resistance, waterproofing, axial load-bearing capacity, impact resistance, and the lifespan of cone rollers are all critical in the selection process. For material drop heights above 6 meters, Spring-Loaded Rollers are generally preferred to minimize belt damage and enhance protection.

Extending the Life Span of Spring-Loaded Rollers:

1.Seal Inspection:

Meticulous checking of roller seals – the "heart" of the roller – is essential for maintaining the vitality of the bearings.

2.Lubrication:

Timely lubrication of the roller bearing housings ensures smooth operation and reduced wear.

3.Waterproof Belt Selection:

Depending on the environmental conditions, opting for waterproof conveyor belts can further protect the rollers from moisture damage.

4.Roller Rest Periods:

During holidays or downtime, it is advisable to remove Spring-Loaded Rollers from their brackets to prevent deformation and maintain the integrity of the seals.

Conclusion:

The Spring-Loaded Roller from Xiamen Mining Conveyor Belt is more than a component; it is a testament to a commitment to longevity and efficiency in the conveyor belt industry. Its capacity to withstand the relentless abuse of material handling operations makes it a valuable asset in any conveyor system. With an emphasis on thoughtful design, meticulous maintenance, and strategic installation, the Spring-Loaded Roller ensures your conveyor system operates seamlessly and economically for extended periods. Embrace the robustness and reliability that Xiamen Mining Conveyor Belt's Spring-Loaded Rollers offer, and let them transform the resilience of your material handling operations.