Conveyor Belt Elevates Material Handling with the New Triple Roller manufacture

"Xiamen Mining's Triple Roller sets new standards in material handling with self-correcting capabilities, durability, and ease of maintenance. Ideal for varied industries, it ensures precise, efficient operations."

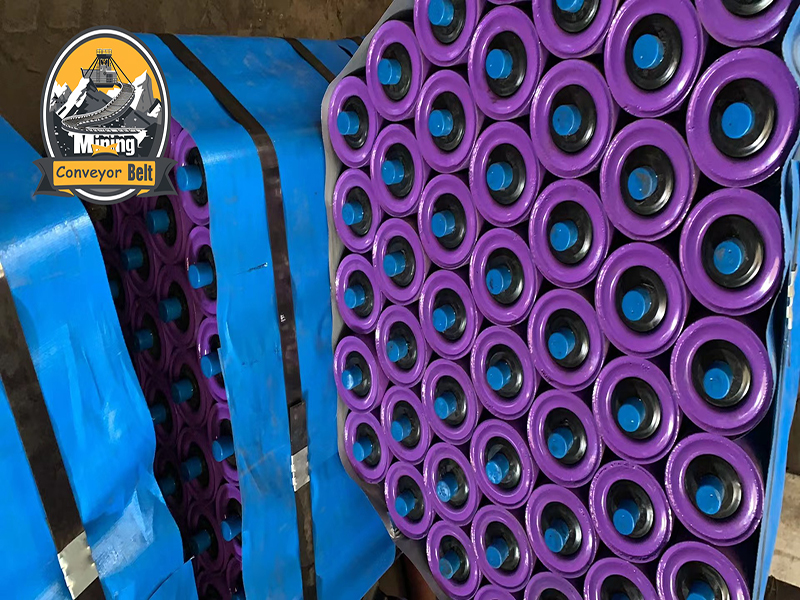

Xiamen Mining Conveyor Belt is revolutionizing the industry standards with the introduction of the Triple Roller, an advanced solution for heavy-duty material handling operations. Engineered for performance, durability, and ease of maintenance, the Triple Roller is the ideal choice for businesses seeking to elevate their conveyor system capabilities efficiently.

Triple Roller: The Optimal Synthesis of Design and Functionality

Our Triple Roller range is meticulously designed to cater to various operational needs:

The 800mm belt direct roller comes with a model of φ89*950, featuring exposed shaft lengths of 65mm on each end and a flat 15mm with a card.

The 800mm belt Triple Roller is modeled as Φ892753 with each exposed shaft length being 25mm.

For the 1000mm belt, the Triple Roller model is Φ1083753, with each exposed shaft length being 30mm.

The 800mm belt buffer roller is designed as Φ120*260 with each exposed shaft length being 40mm and a flat 30mm.

Similarly, the 1000mm belt buffer roller is modeled as Φ120*375, with each exposed shaft length being 20mm and a flat 15mm.

Widely Applicable Across Industries

The Triple Roller is employed across a spectrum of sectors including material factories, mining operations, machinery plants, coking plants, steel mills, cement, metallurgy, and coal mining, proving its versatility and ability to handle diverse material handling challenges.

Usage and Operation

Before utilizing the Triple Roller, it is crucial to:

1.Inspect the roller for any visible damage or severe impacts and ensure that it rotates smoothly without obstructions.

2.Install the rollers at distances that are scientifically calculated based on the type of materials and characteristics of the conveyor, avoiding overly sparse or dense installations to prevent potential friction and wear.

3.Install the rollers in a manner that prevents them from rubbing against each other to maintain optimal performance.

Unparalleled Manufacturing Quality

Xiamen Mining employs state-of-the-art design and manufacturing techniques to elevate our rollers to higher standards. Our rollers boast minimal rotational resistance, extended lifespan, low maintenance needs, and high load-bearing capacities. The steel tubes used are high-frequency welding pipes, with internal deburring for precise roundness. Shafts are cold-drawn steel, machined to standard tolerances. Bearing housings are made from imported cold-stamped steel plate, shaped through multiple stamping processes and then welded by automatic welding machines to ensure a high degree of structural integrity.

The Structural Advantage

The Triple Roller is constructed using a three-roller hinge assembly, where three rollers are connected by linking plates and then suspended on the conveyor's crossbeam using hooks. This design grants the Triple Roller excellent self-balancing properties, helping prevent belt misalignment. In case of belt misalignment, material redistribution during operation causes deformation of the roller group's plane and an asymmetrical load on the side rollers. The side roller facing the direction of misalignment has a larger inclination angle than the opposite side, which generates a self-aligning force counteracting the drift, realigning the belt. This unique feature ensures that the conveyor belt operates smoothly under various conditions, including loading errors, temperature changes, and wind direction variability.

In conclusion, Xiamen Mining Conveyor Belt's Triple Roller is more than just a component; it embodies the innovation and reliability that the company is renowned for. Offering remarkable self-correcting capabilities and designed with the user's needs in mind, the Triple Roller is set to become an indispensable part of material handling operations that demand precision, durability, and operational excellence. Choose the Triple Roller for a seamless, cost-effective, and efficient conveying solution.