Main features of patterned conveyor belts

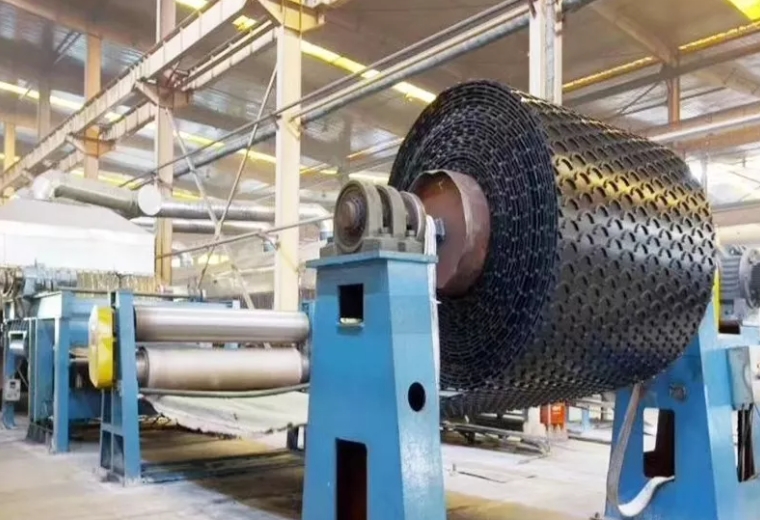

The patterned conveyor belt is composed of a belt body and a pattern part. Due to the different materials being transported and the size of the conveyor inclination angle, the shape of the pattern is required to be different in height, depth and shallowness. There is a "human" shaped pattern on the surface that is higher than the belt body. Each pattern can be divided into three types: high, medium and low.

Product advantages: Suitable for conveying powdered, granular and small pieces of materials with an inclination angle of ≤40 degrees. It can also convey packaging bag materials.

Main features:

1. During transportation and storage, the conveyor belt should be kept clean, avoid direct sunlight, rain and snow, prevent contact with acids, alkalis, oils, organic solvents and other substances that affect the quality of rubber, and be 1 meter away from the heating device.

2. During storage, the temperature in the warehouse should be kept between 15℃+40℃. The relative temperature should be kept between 50-80%.

3. During storage, the conveyor belt must be placed in a roll and must not be folded. It should be turned over once every season during storage.

4. The conveyor belt running speed should not exceed 50 m/s. When transporting large-sized and abrasive materials and using fixed plow-type unloading devices, low speed should be used as much as possible. If the speed exceeds the specified speed, it will affect the service life of the belt.

5. The relationship between the diameter of the conveyor's drive roller and the conveyor belt cloth layer, the matching of the drive roller and the redirection roller, and the requirements for the roller groove angle should be reasonably selected according to the design regulations of the conveyor.

6. The following matters should be noted when using the conveyor belt:

A. Avoid the rollers being covered by materials. Cause poor rotation, prevent leakage from being stuck between the roller and the belt, pay attention to the lubrication of the moving parts, but do not oil the conveyor belt.

B. Try to avoid starting with load.

C. If the belt deviates, measures should be taken in time to correct it.

D. If local damage to the belt is found, it should be repaired in time to avoid expansion.

E. Avoid the belt from being blocked by the frame, pillars or block materials to prevent it from being broken and torn.